The collision of an F-35C fighter with an aircraft carrier in January damaged not only the ship's deck, but also an EA-18G Growler electronic warfare jet. Pieces of the stealth fighter ended up piercing the fuselage of the aircraft, which was parked on the USS Carl Vinson.

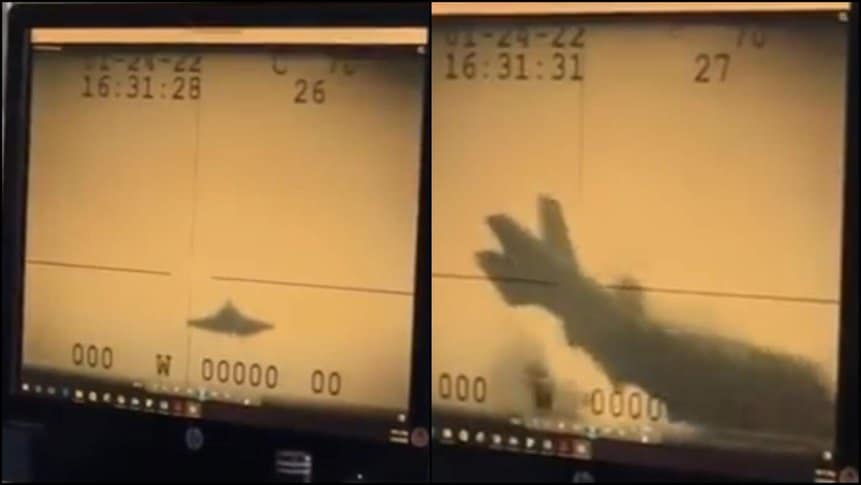

On January 24, an F-35C from the VFA-147 Argonauts squadron suffered the so-called “ramp strike” when trying to land on the USS Carl Vinson, during operations in the South China Sea. Weeks after the first images with the plane at sea appeared on the internet, two videos showing the accident were leaked on the net.

When colliding with the deck (called a deck on an aircraft carrier), the landing gear collapsed and the plane caught fire, sliding sideways across the deck until it fell into the sea. Seven soldiers were injured: six sailors who were on board the ship and the fighter pilot, who ejected and was rescued.

In early March, the Navy (USN) announced that it had recovered the fighter from the bottom of the China Sea, adding that the jet was at a depth greater than 3,77 kilometers (12,400 feet).

However, only yesterday the USN revealed that another plane suffered damages due to the accident. According to Naval Air Systems Command (NAVAIR), an EA-18G of the VAQ-136 Gauntlets Electronic Strike Squadron suffered a puncture in the S9 skin between the Y631 and Y645 fuselage airframe trainers.

The supersonic jet was then sent to the Fleet Readiness Center Southwest (FRCSW) at Naval Air Station North Island in California, where it has been receiving repairs.

“Because of the Command's investments in the latest technologies and maintenance and restoration systems, the estimated repair time will be approximately 50% less than purchasing Growler components from the aircraft's original manufacturer, Boeing,” highlighted NAVAIR.

“The repair plan is to take out the vertical stabilizer to remove the S9 and S10 liners. We will replace the S9 case and hope to save the S10 case after evaluating it with a non-destructive inspection (NDI)”, said Ehren Terbeek, F/A-18 Legacy and F/A-18E/F program manager.

“We'll need to NDI the Y631 former to make sure there are no cracks, replace the covers and put the tail back on. If we don't have to replace the previous Y631 or S10, it should be around 4.500 working hours or about nine months.”

The Growler's mold is made of aluminum, and once the material is received, manufacturing the component should take about three weeks, Terbeek said. Manufacturing costs total approximately $208.000.

Terbeek explains that the command will manufacture the former Y645 former using its Flexible Manufacturing Cell (FMC) in Building 472. It will be the first Growler part produced at the FMC.

The manufacturing cell is the first of its kind at the Department of Defense and is comprised of six five-axis CNC (Computer Numerical Control) machines and a pallet system manufactured by DMG-Mori and Fastems, respectively. FMC attachment and pre-programmed parts were initially designed to support the F/A-18 Hornet fighter and E-2 Hawkeye and C-2 Greyhound landing gear.

CNC machines are capable of milling, turning and grinding within one machine and can be used on parts and components made from aluminum, steel and titanium.

“Of that amount, approximately $107.000 would be for non-recurring charges for modeling, programming and proofing due to the fact that this is the first time it is being manufactured; plus material is $23.906”, Terbeek said.

Do you want to receive our news firsthand? Click Here and be part of our Group on Whatsapp or Telegram.